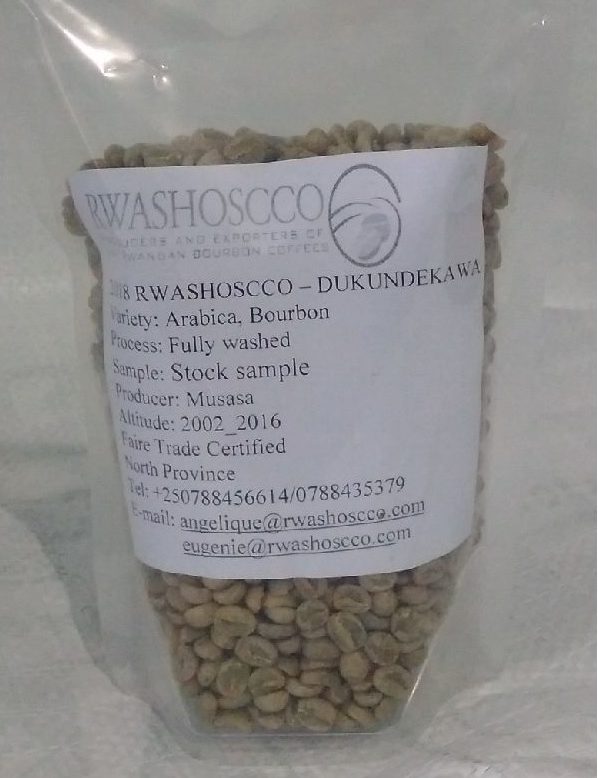

Dukundekawa – Musasa

Stock Sample – Dukundekawa Musasa

Categories: All- Coffee, Green Beans, Organic

Related Products

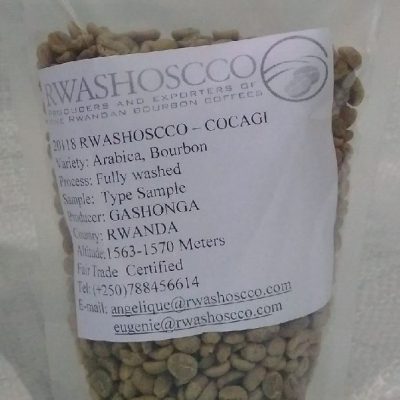

Cocagi – Gashonga

Stock Sample Cocagi – Gashonga

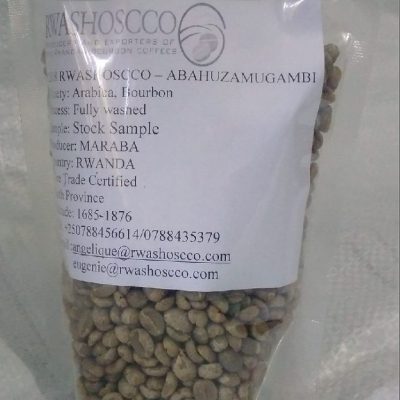

Abahuzamugambi ba kawa – Maraba

Stock Sample – Abahuzamugambi ba Kawa

Green – Coffee Beans

Green Coffee Beans

At Rwashoscco, We offer quality green beans direct from our farmers in six coffee growing regions of Rwanda.

Origin, Producers and Process information:

Growers: Smallholder farmers organized in 6 cooperatives with each accounting members and washing stations.

Regions: South, North, Est and West Rwanda.

Altitude: 1500 – 2200 meters above the sea level.

Process: Triple washed – Cherries floated prior to pulping and fermentation, fully washed, then soaked overnight in clean water. Dried on raised beds with protection from seasonal rains.

Cultivar: Red Bourbon Arabica.

Reviews

There are no reviews yet.